Understanding the Physical Properties and Qualities of Nylon PA12 in MJF 3D Printing

In the rapidly evolving world of additive manufacturing, it’s crucial to understand the materials we work with, their properties, and how they affect the final product. One material that has gained significant traction for its versatile qualities is Nylon PA12. When produced using Multi Jet Fusion (MJF) 3D printing technology, Nylon PA12 showcases an impressive array of physical properties, making it an ideal choice for numerous applications. In this blog post, we’ll delve into the distinctive attributes of Nylon PA12, exploring why it’s a preferred material in the MJF 3D printing landscape.

IWhat is Nylon PA12?

Nylon PA12, also known as Polyamide 12, is a type of nylon that offers a balance between flexibility and strength. It’s known for its durability, chemical resistance, and smooth surface finish. These qualities position it as a standout choice for functional prototypes, end-use parts, and complex geometries.

Multi Jet Fusion technology, combined with Nylon PA12 opens new doors for innovation and production efficiency.

IKey Physical Properties of Nylon PA12 in MJF 3D Printing

1 Mechanical Strength

Nylon PA12 offers remarkable tensile and compressive strength. With a tensile strength of approximately 48 MPa and elongation at break around 20%, parts printed in PA12 can withstand significant stress and strain. This makes it suitable for creating mechanically demanding components like hinges, clips, and functional prototypes.

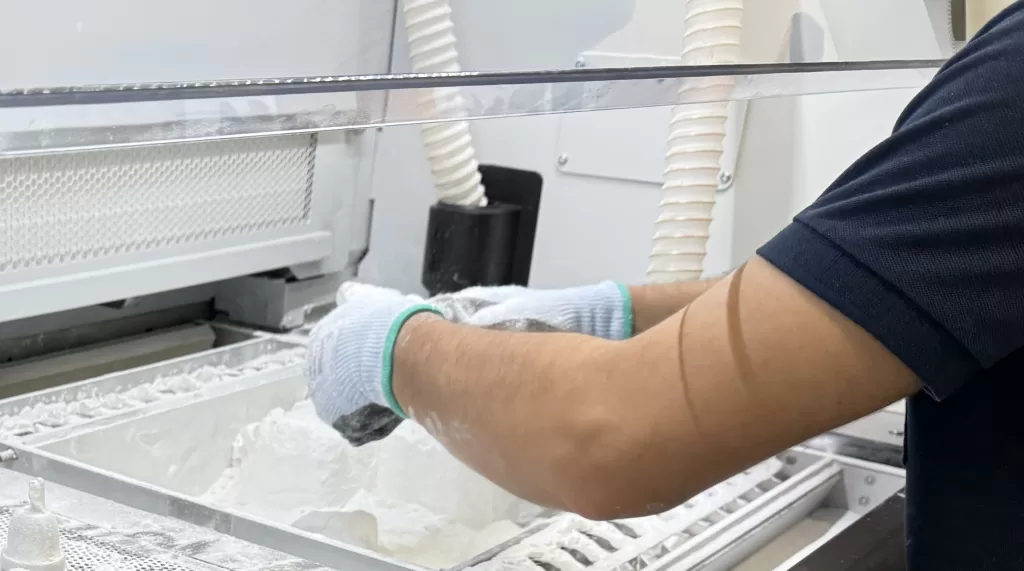

2 Surface Finish

One of the standout features of Nylon PA12 when printed using MJF technology is its surface finish. The parts tend to have a smooth, high-quality finish that requires minimal post-processing. This smoothness not only enhances aesthetic appeal but also contributes to the usability of moving parts, reducing friction-related wear.

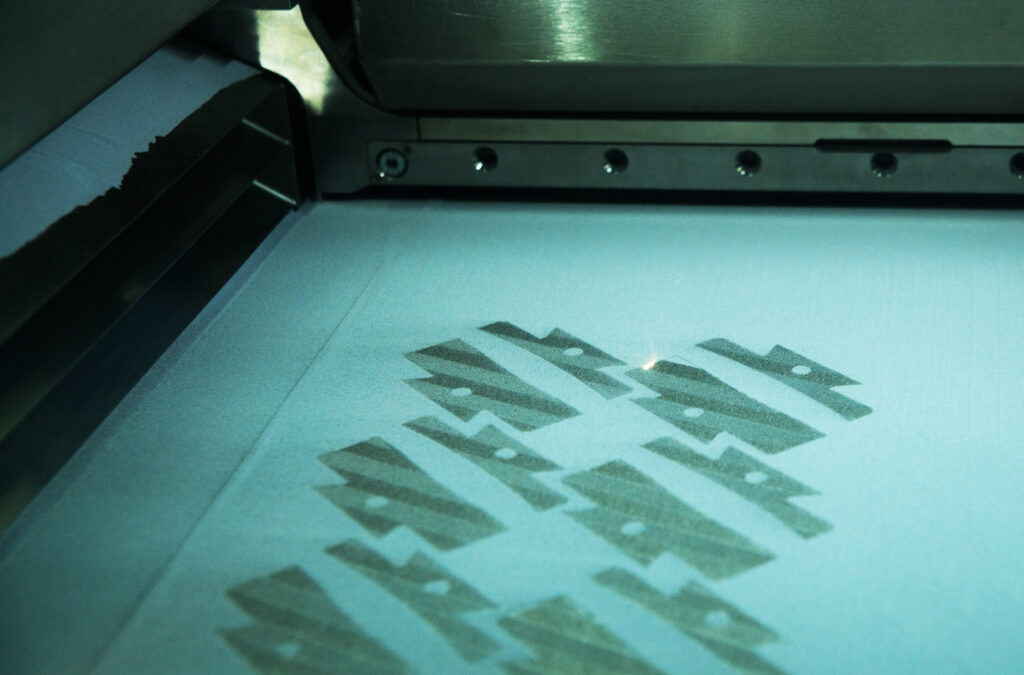

3 Precision and Detail

MJF technology excels at creating parts with high precision and fine details. Nylon PA12 complements this capability by maintaining dimensional stability, ensuring that complex geometries and intricate features come out accurately. This precision is particularly crucial for applications in aerospace, medical devices, and detailed models.

4 Dimensional Accuracy

Nylon PA12 exhibits excellent dimensional fidelity when printed with MJF. The material has low shrinkage and warping tendencies, which translates to consistent part dimensions and tight tolerances. This property is essential for applications requiring interoperability, such as mechanical assemblies and functional prototypes.

5 Chemical Resistance

Nylon PA12 is known for its superior resistance to a wide range of chemicals, including oils, fuels, and solvents. This property makes it an exceptional choice for parts that will be exposed to harsh environments or chemical agents. Industries such as automotive and industrial manufacturing benefit significantly from this characteristic.

6 Thermal Stability

With a melting point around 178°C and good thermal stability, Nylon PA12 can handle higher operational temperatures compared to other 3D printing plastics. This characteristic broadens its application range, from everyday consumer products to more specialized environments where thermal performance is critical.

7 Water Absorption and Environmental Resistance

Nylon PA12 exhibits lower water absorption rates compared to other nylons, which means the mechanical properties remain stable even in humid conditions. This resistance makes it a suitable material for outdoor applications and parts exposed to varying environmental conditions.

IAdvantages of Using Nylon PA12 in MJF 3D Printing

IOur Conclusions

[row_inner_3] [col_inner_3 span__sm=”12″]Nylon PA12, when used with MJF 3D printing, presents a valuable material with properties well-suited for a wide variety of applications. Its mechanical strength, chemical resistance, and excellent surface finish make it a reliable choice for professionals across industries. Understanding these qualities allows designers and engineers to leverage Nylon PA12’s full potential, pushing the boundaries of what’s possible with 3D printing technology.

At Upsurge, we are committed to helping you harness the power of advanced materials like Nylon PA12 through innovative 3D printing solutions. Whether you’re looking to prototype a new design, create a custom component, or explore the endless possibilities of additive manufacturing, Nylon PA12 with MJF printing offers a competitive edge in precision, durability, and efficiency. Reach out to us today to learn more about how this remarkable material can elevate your next project.

Visit our 3D Printing technology and material section here.

Contact us for more info.

Check out HP’s website for more MJF 3D Printing materials.