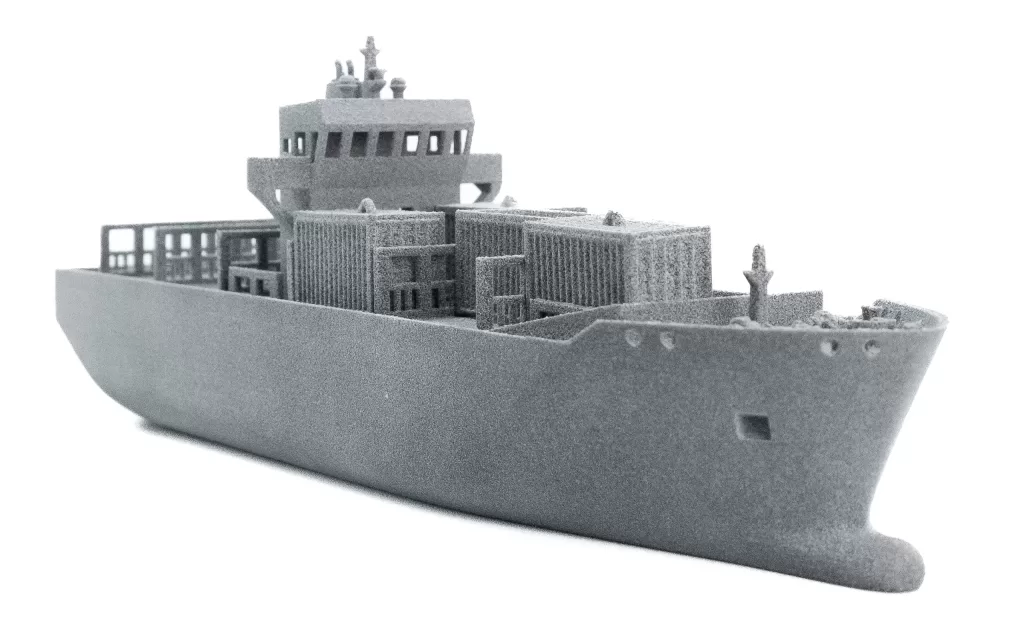

Revolutionizing the High Seas: How Multi Jet Fusion (MJF) is Transforming the Maritime Industry

The HP Multi Jet Fusion technology is exceeding expectations, and the finished products are significantly different from the fragile plastic items commonly associated with other 3D printing methods.

MJF allows for the creation of durable, highly resistant, and incredibly precise functional prototypes and small batches that are ready for use. These items are produced quickly and at a relatively low cost.

This post is about the advantages offered by MJF 3D printing to the maritime industry, ranging from operational efficiencies to innovation in design and reduced environmental impact.

IMulti Jet Fusion enables rapid prototyping and production. Through swift design iteration cycles, engineers can quickly develop and test new components. This reduces the time from concept to functional parts, allowing for faster production of complex items. As a result, companies can significantly speed up their time to market, ensuring they stay competitive and responsive to industry demands and technological advancements.

ICustomization and small batch production are streamlined with Multi Jet Fusion technology. It allows for the creation of tailored solutions to fit specific maritime operations, enhancing both performance and reliability. Unlike traditional manufacturing, which requires large production runs to be economical, MJF offers a cost-effective method for producing smaller quantities without the need for expensive tooling.

IMJF revolutionizes manufacturing through exceptional design freedom and functional integration. It enables the production of complex, lightweight structures often impossible with traditional methods, fostering innovative design approaches for improved performance and fuel efficiency. Additionally, MJF supports the creation of parts with integrated functionalities, significantly reducing the number of components and potential points of failure, thereby enhancing overall system reliability and efficiency.

IOn-demand manufacturing of spare parts minimizes the need for large inventories and storage, especially beneficial in remote maritime locations where supply chain logistics are challenging. Rapid production of replacement parts results in reduced downtimes for repairs and maintenance, significantly boosting operational efficiency.

IMaterial utilization is optimized through a powder-based process that offers high material reusability, significantly reducing waste and costs. Additionally, MJF eliminates the need for expensive molds and tooling, making it an economically advantageous solution for low-volume production runs.

IThe MJF process not only ensures strong and durable materials that can withstand harsh maritime environments but also contributes to environmental sustainability through lower material waste, resulting in a smaller environmental footprint. Additionally, MJF is more energy-efficient compared to traditional manufacturing methods that require extensive machining and finishing, further enhancing its appeal for optimizing lightweight, high-strength components that improve fuel efficiency and durability.

IIn conclusion, MJF 3D printing offers the maritime industry a versatile tool to improve manufacturing processes, reduce costs, and foster innovation in design and production. These advantages collectively contribute to more efficient and sustainable maritime operations.

At Upsurge, we can help you create a digital library for your spare parts, scan an obsolete part and print on demand, we can manufacture anything from proptotypes to small batches of parts.

Contact us for more information, we are always happy to help.

Click here for more information on the HP MJF 5200 3D printer.