Upsurge: 3D Printing Services with MJF Technology

Welcome to www.upsurge3d.com, where we dive deep into the world of advanced 3D printing services that are reshaping the horizon of manufacturing. Amongst the cutting-edge technologies, Multi Jet Fusion (MJF) stands out, offering unprecedented capabilities across a plethora of industries. Here, we explore how manufacturing-grade 3D printing, especially with MJF, is not just changing the game—it’s rebuilding the entire playing field.

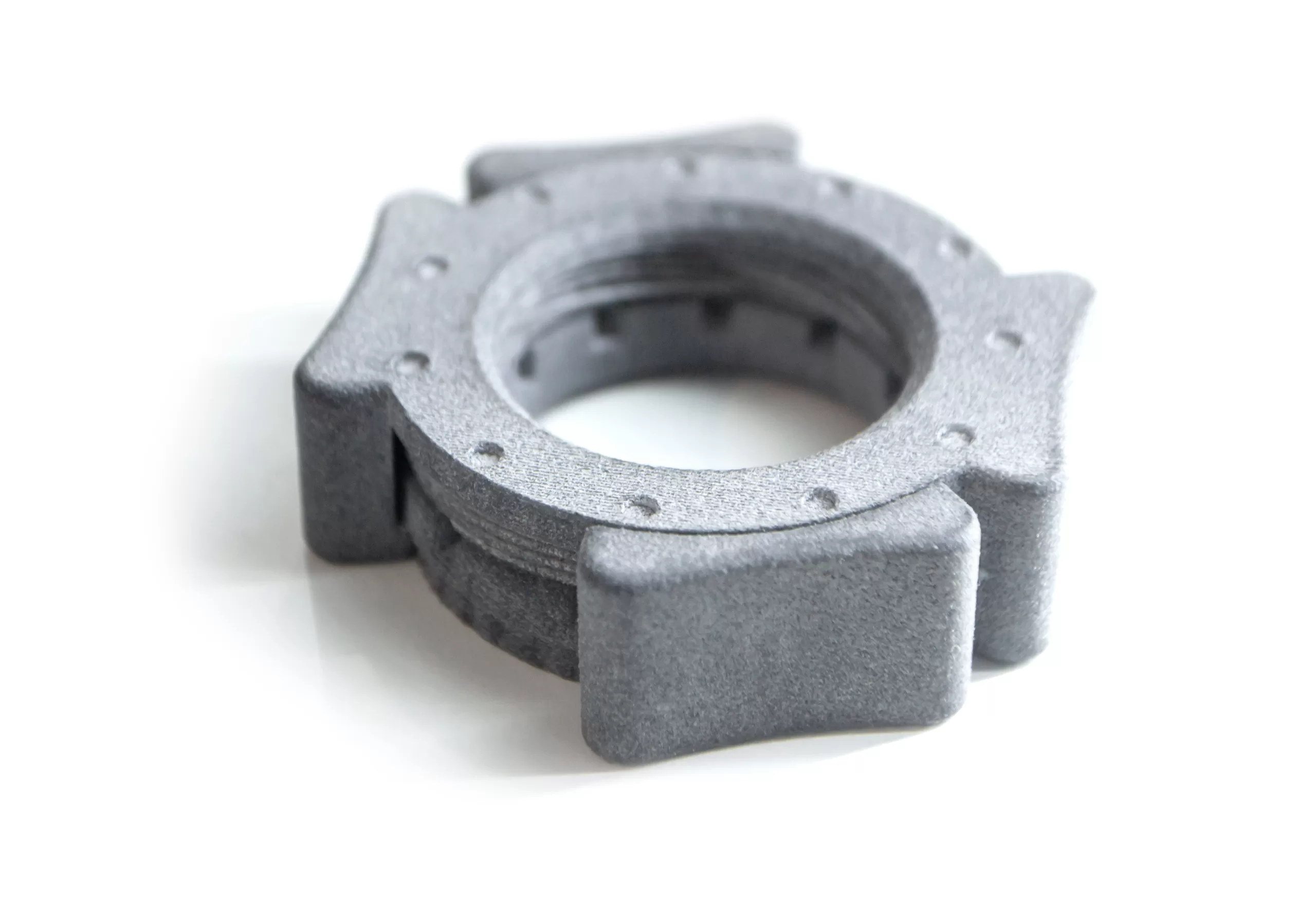

In today’s fast-paced market, manufacturers are under constant pressure to innovate rapidly while maintaining cost and time efficiency. This is where Multi Jet Fusion steps in as a game-changer. Developed by HP, MJF technology allows for the production of highly detailed, durable parts with superior surface finish and mechanical properties. It opens up new frontiers in design flexibility, making it an ideal solution for numerous industries looking to push their innovative boundaries.

Take, for instance, the automotive industry—rife with demands for higher performance and customization. Companies are harnessing MJF technology to produce lightweight components that match the strength of traditionally manufactured parts but offer the added benefits of reduced material usage and weight. This leads to increased fuel efficiency and performance in vehicles, translating directly to sustainability goals. Prototypes that once took weeks to fabricate are now produced in days, allowing automotive developers to iterate and innovate at breakneck speed.

In the world of healthcare, MJF has proven to be a beacon of hope for personalized medicine. From custom prosthetics to patient-specific surgical guides, the ability to tailor-make devices that seamlessly fit the human body is revolutionizing patient care. The precision and reliability of MJF ensure that each medical tool or device not only meets but exceeds the stringent demands of medical conformity. Instances where patient recovery timelines have been drastically reduced thanks to customized implants underscore the transformative power of additive manufacturing in medical science.

Another fascinating application is found in the field of consumer electronics. As gadgets become more sophisticated and compact, the components that power them must also evolve. MJF technology enables the production of complex geometries that current electronic designs demand, without the exorbitant costs of traditional manufacturing methods. This fosters a selffueling cycle of innovation, where consumer demands catalyze design breakthroughs.

In architecture and construction, MJF facilitates the creation of intricate models and construction components with precision unmatched by conventional techniques. Architects can now breathe life into their most imaginative designs, producing models that offer clients a tangible experience of their future structures. The scalability of MJF also allows for the production of full-scale parts for construction uses, driven by eco-friendly materials that contribute to sustainable building practices.

At Upsurge 3D, we’re not just passive observers of these industrial revolutions. We actively collaborate with visionaries across sectors to harness the full potential of manufacturing-grade 3D printing. Whether it’s engineering the next generation of electric vehicles, designing patient-centered medical devices, or crafting groundbreaking electronic components, we’re at the heart of each transformative journey.

By adopting MJF technology, manufacturers are not only leveling manufacturing efficiencies but are also investing in their capacity to refashion the world. As we move forward, the symbiotic relationship between technological innovation and human creativity will chart the course for 3D printing services. We are proud to be at the forefront of this movement, equipped and excited to transform the present while dreaming of the possibilities for tomorrow.

Visit www.upsurge3d.com to learn more about how our manufacturing-grade 3D printing services, powered by MJF technology, can be the catalyst for your next big idea. Let’s build the future, layer by layer.