End-to-end 3D CAD modeling

Mechanical and organic shape optimization

Support for complex geometries and overhangs

Reverse engineering from physical samples

Material and structural input based on application

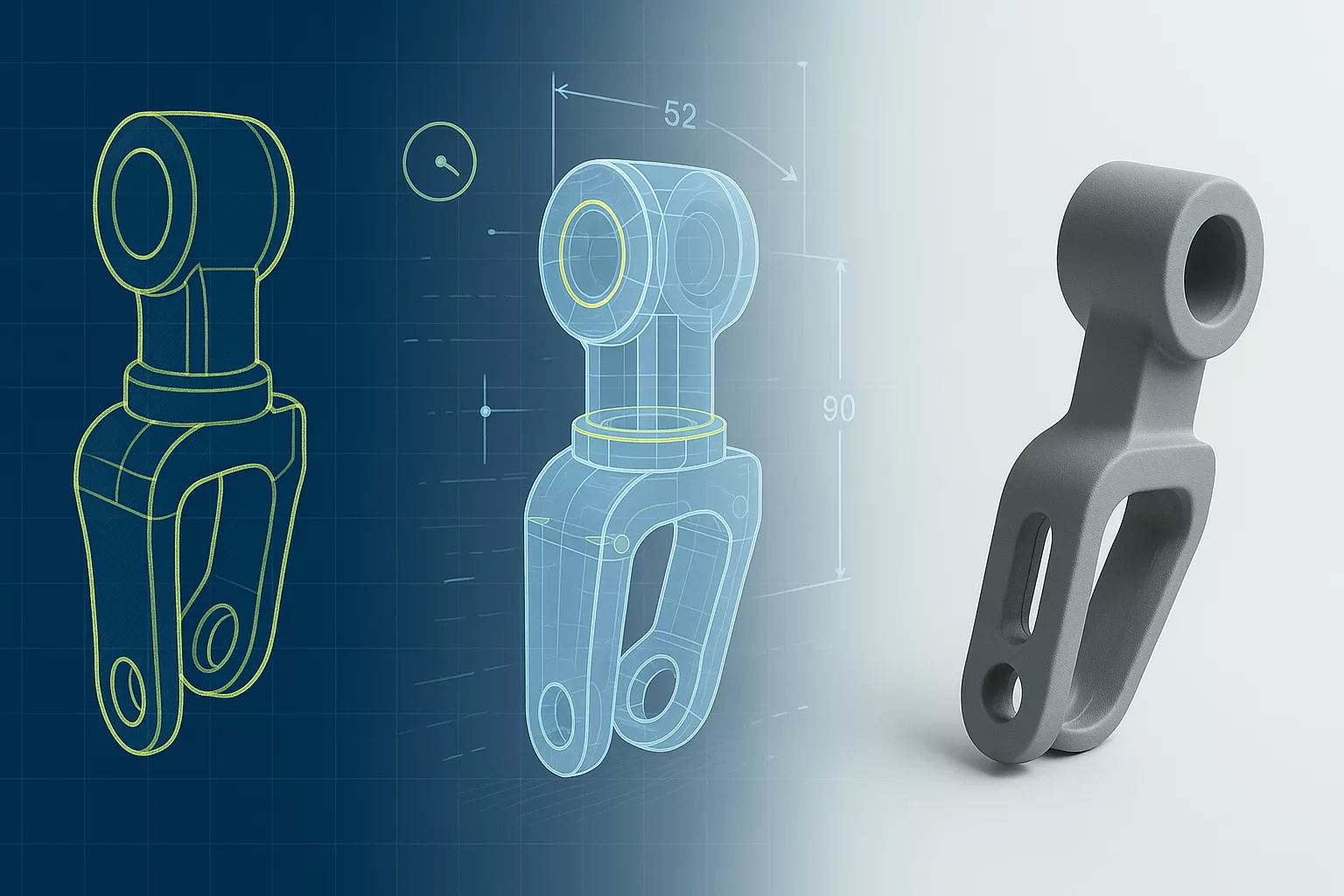

From Concept to CAD: Your Design Starts Here

Every great product starts with a clear idea—and we help shape it into a manufacturable model. Upsurge transforms sketches, rough models, or existing designs into detailed, production-ready 3D CAD files.

We approach design as a collaborative process, helping you explore functionality, geometry, and structural integrity right from the start. Whether you’re a startup testing a prototype or an engineer refining a complex part, we bring clarity, speed, and precision to your design workflow.

Optimized for Performance and Printability

Designing for 3D printing isn’t just about geometry—it’s about how a part performs during and after manufacturing. We apply Design for Additive Manufacturing (DfAM) best practices to ensure your parts are not only printable but also structurally sound, efficient, and cost-effective.

Our team understands how design decisions affect print success and part behavior under load. From internal supports to material constraints, we tailor every model to meet the needs of HP MJF technology and your intended use.

Design Guidelines for MJF

Minimum wall thickness: 0.7–1.0 mm

Standard tolerance: ±0.3 mm or ±0.3%

Maximum build size: 380 x 284 x 380 mm

Drain holes for internal voids: 4 mm+

CAD Model Checks

Watertight geometry

Orientation-aware modeling

Surface optimization

Snap fits and mechanical joints

Ready to Bring Your Product to Life?

Submit your project details or request a consultation. We’ll review your goals, help scope your design, and get you a print-ready solution—fast.

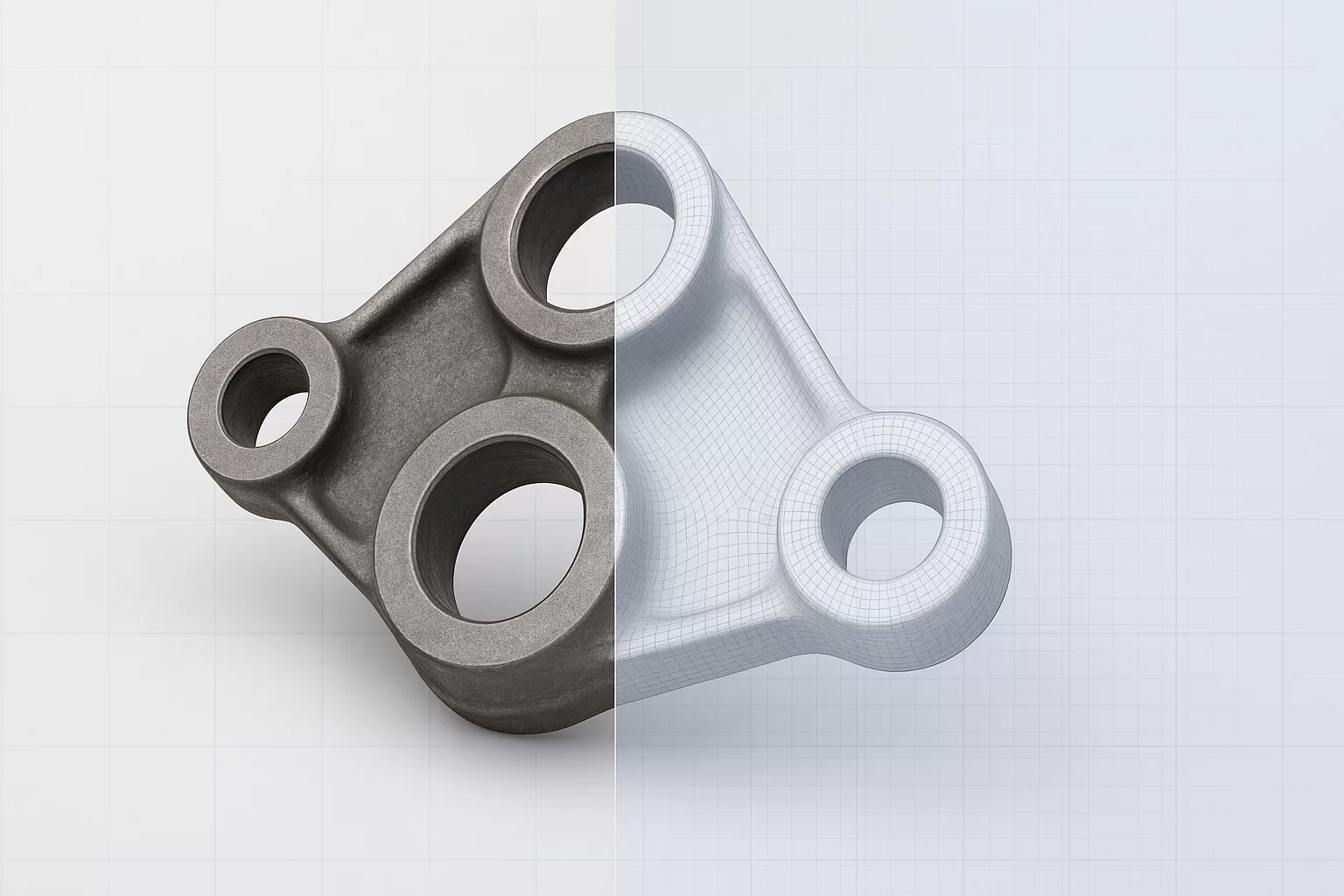

High-Precision 3D Scanning Services

Capture real-world parts with micron-level accuracy. Upsurge offers professional 3D scanning services to help you digitize, inspect, or reverse-engineer existing components—fast and reliably.

Accurate scans for design, replication, or quality control

Ideal for legacy parts, prototyping, and reverse engineering

Compatible with CAD modeling and additive manufacturing

Fast turnaround and seamless file delivery

What We Scan

Mechanical parts

Prototypes

Enclosures and housings

Custom fixtures or tools

Organic shapes for design adaptation

Output Options

High-resolution mesh (.STL or .OBJ)

Parametric solid models (.STEP or .IGES)

Surface reconstructions for CAD workflows

Need to scan a part?

[Request a Quote]

Design Guidelines for MJF 3D Printing

To get the best results from your project, we recommend following a few key design principles when preparing parts for 3D printing. Multi Jet Fusion offers greater design freedom than traditional methods, allowing for more intricate structures, but it also requires a shift in how parts are designed. By considering early whether your product is intended as a prototype, a final part, or for mass production in another technology such as injection molding, you can save time, reduce costs, and ensure a successful outcome.

Reach out to us at design@upsurge3d.com and we’ll help you determine the best approach for your project. You can also download our Design Guidelines to get practical tips on making the most of our technology.