Technology

I HP Multi Jet Fusion 5200

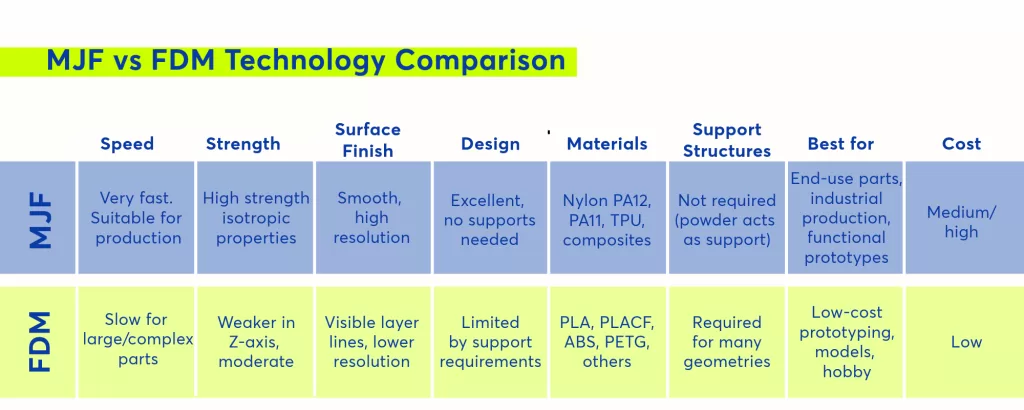

We print using HP’s latest technology, the Multi Jet Fusion 5200, an industrial 3D printer with unbeatable quality, speed, and high productivity. Simply put, MJF fuses nylon powders layer upon layer to create solid objects. The powder bed offers complete design freedom without the need for support structures. Multi Jet Fusion produces high-precision objects with complex geometries at a high speed, perfect for for detailed prototyping or end-use parts suitable for many industrial applications.

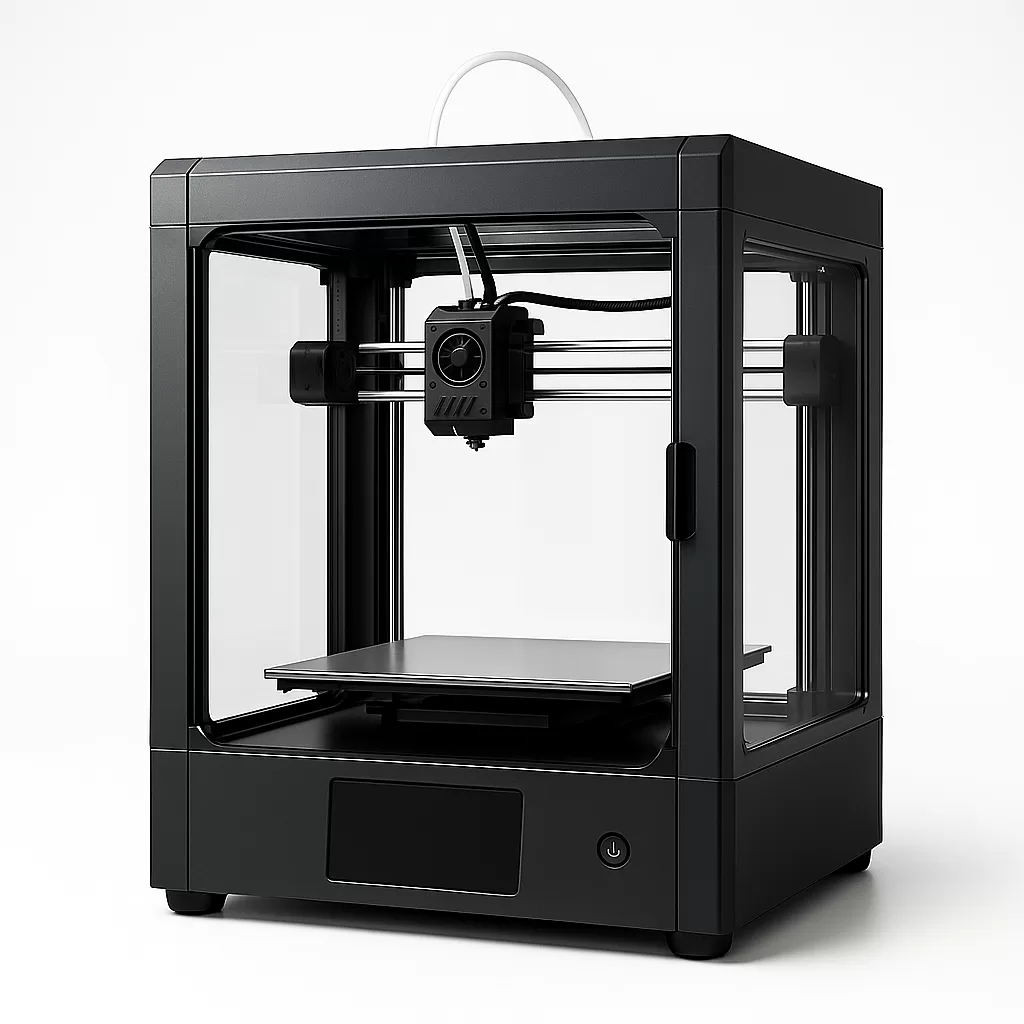

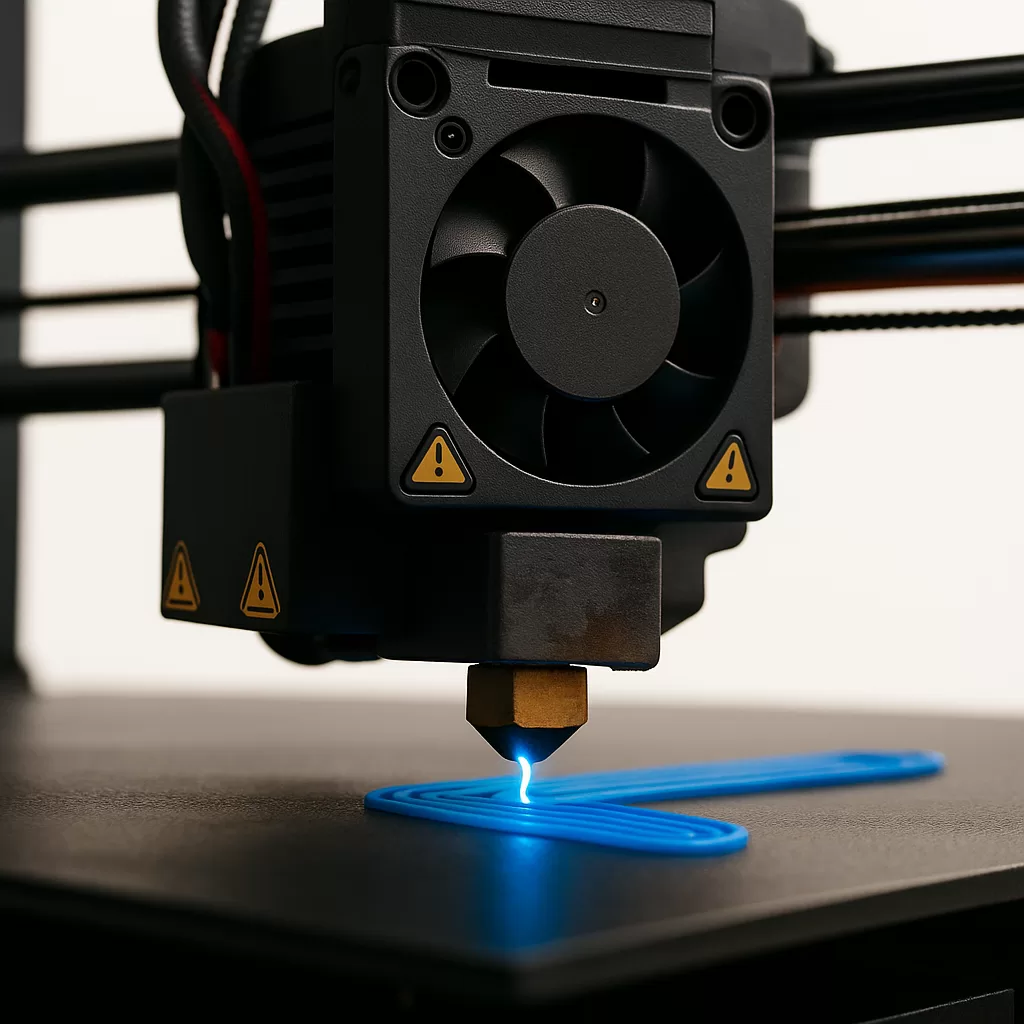

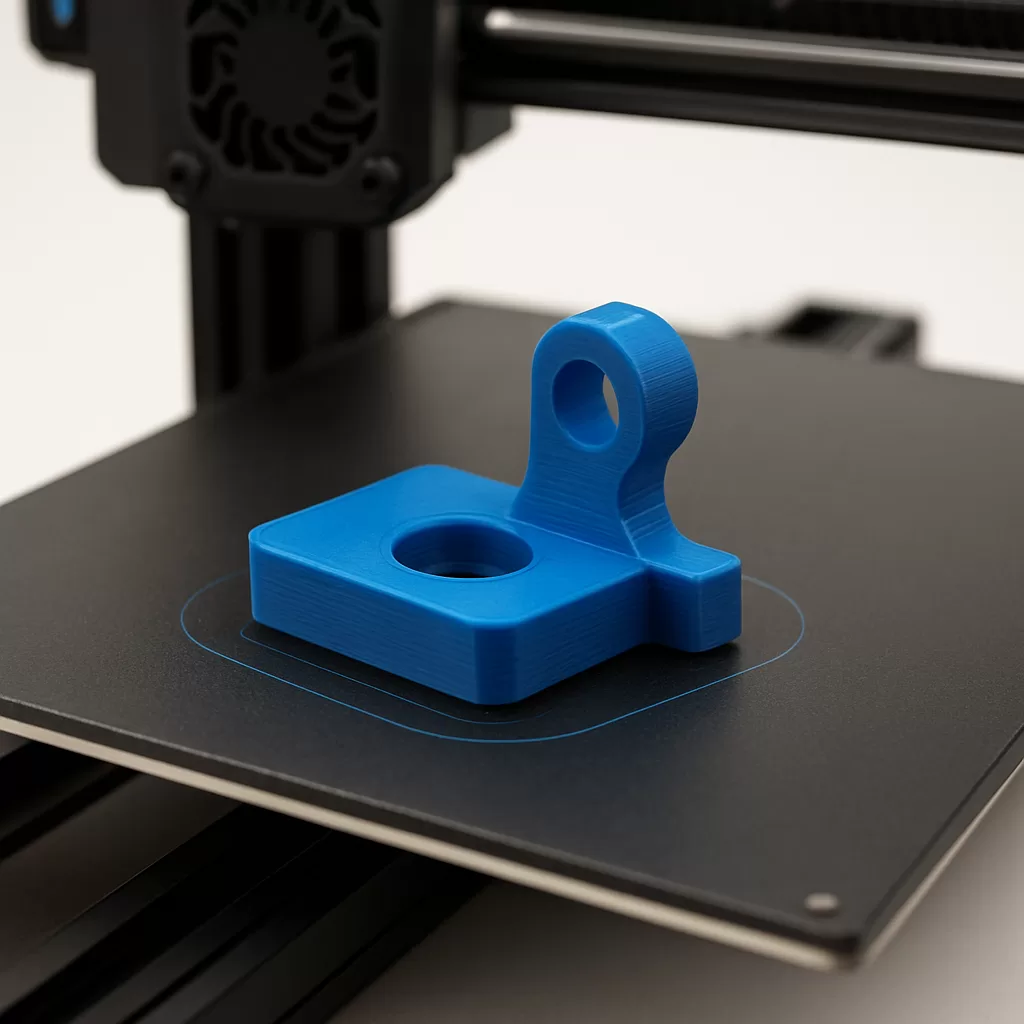

I Fused Deposition Modeling 3D Printing

FDM is one of the most popular and cost-effective 3D printing methods. It works by extruding melted thermoplastic filament layer by layer to create solid parts. Perfect for quick prototypes, visual models, and simple functional components, FDM offers versatility with materials like PLA, ABS, and PETG.

While not as fast or strong as industrial technologies such as MJF, it’s an affordable option for early-stage designs and everyday projects.

Materials

Multi Jet Fusion

I Polyamide 12

Nylon PA12 is one of the most used materials in MJF manufacturing, for good reason. It is a thermoplastic polymer that creates strong, reliable parts with excellent physical and mechanical properties. It is resistant to abrasion, oils, and other chemical agents, and it has low moisture absorption. PA12 guarantees durability and high surface resolution. The characteristics of this thermoplastic allow it to be used across a wide variety of environments and industries. With this type of nylon, your parts will resist impacts without being damaged and will resist repeated use. Plus, it has a low production cost.

Fused Deposition Modeling

I PLA (Polylactic Acid)

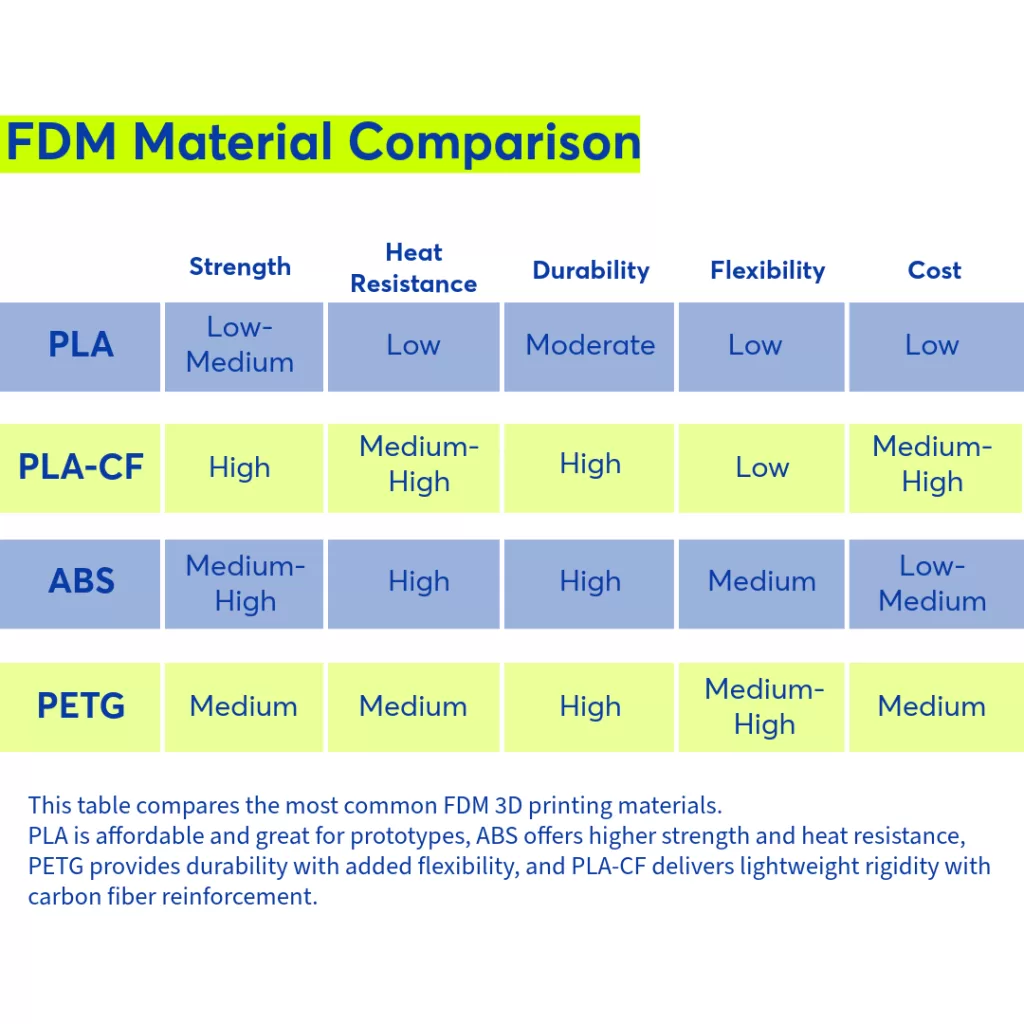

PLA is one of the easiest and most sustainable materials to print with. Made from renewable resources, it offers excellent surface finish and detail, making it perfect for prototypes, models, and visual parts.

I PLA-CF (Carbon Fiber Reinforced PLA)

PLA-CF takes PLA to the next level by blending it with carbon fibers. This composite material delivers higher stiffness, strength, and dimensional stability while remaining lightweight. PLA-CF is ideal for structural parts, jigs, fixtures, and prototypes that need extra rigidity without sacrificing printability.

I ABS (Acrylonitrile Butadiene Styrene)

ABS is stronger and more durable than PLA, with superior impact resistance and higher heat tolerance. It is often chosen for functional parts, engineering applications, and components that need to endure more demanding environments.

I PETG (Polyethylene Terephthalate Glycol)

PETG provides a balance of strength, flexibility, and ease of printing. It has excellent chemical resistance and low moisture absorption, making it reliable for parts exposed to outdoor conditions or mechanical stress.

Together, these materials make FDM a versatile choice — whether you need affordable prototypes, durable functional parts, or lightweight reinforced components for demanding applications.